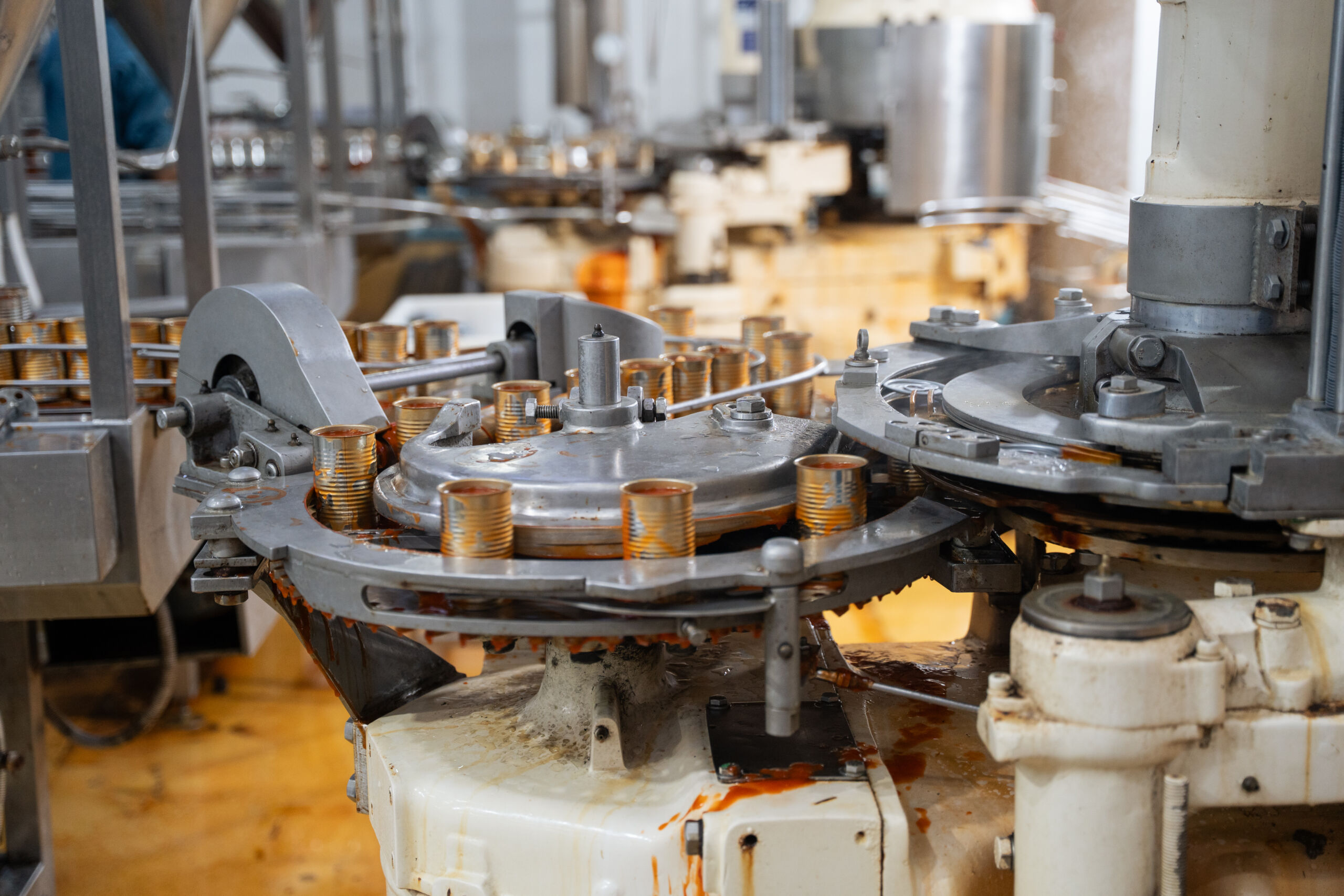

Food processing requires precision, hygiene, and compliance with strict standards. Unicore Automation developed and commissioned a PLC and SCADA-based control system for a food processing plant. The solution automated production lines, integrated temperature and pressure monitoring, and deployed flow and level sensors for accurate batching and ingredient control. Cleaning-in-Place (CIP) automation ensured sanitary operations, while the SCADA system delivered real-time monitoring, production reporting, and alarm handling. This holistic approach guaranteed consistent product quality, improved efficiency, and regulatory compliance. By uniting hygiene with productivity, the project illustrates how Unicore Automation helps food manufacturers maintain high standards while operating at peak performance.