Introduction

PLC Programming Services: How to Optimize Industrial Processes in 2025 is not just a catchy title—it reflects the changing landscape of automation. Businesses worldwide are rethinking how they run their production processes, striving for greater reliability, speed, and overall efficiency. At the center of this transformation are Programmable Logic Controllers (PLCs), designed to deliver precise control and seamless integration across various industries.

By 2025, the rise of Industry 4.0, smart sensors, and data acquisition systems makes PLC programming more than a technical requirement; it is a game-changer for businesses seeking a competitive edge. Done right, programming ensures quality control, reduces downtime, and supports informed decisions at every level of the factory floor.

What is PLC Programming and Why It Matters

A Programmable Logic Controller is an industrial computer that runs Ladder Logic, function block diagrams, or structured text to control machines and processes. Unlike general-purpose PCs, PLC systems are engineered for rugged industrial environments, offering reliability in harsh conditions such as heat, dust, and vibration.

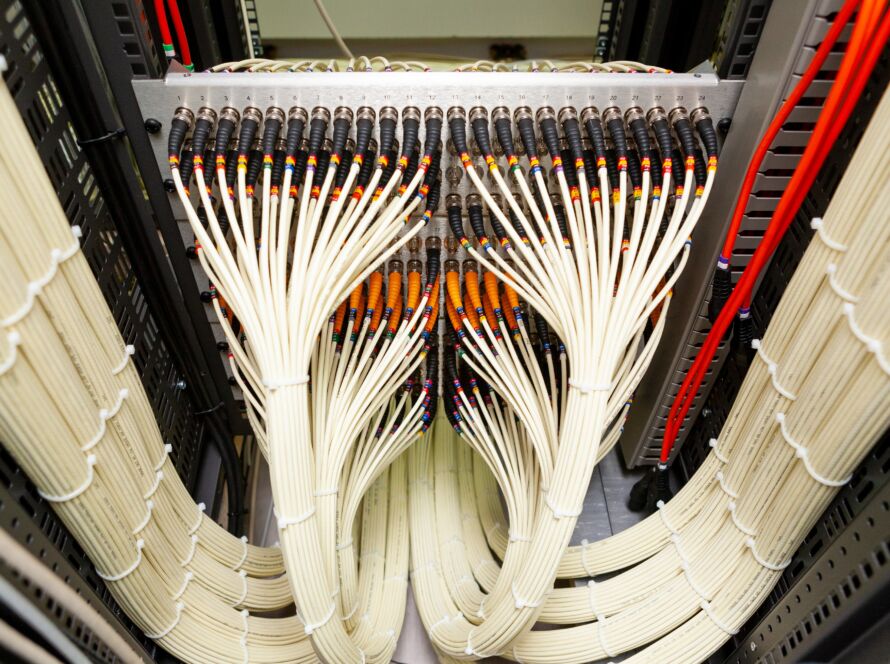

PLCs interact directly with field devices, sensors, and actuators. By processing signals through communication protocols like Ethernet/IP or Modbus, they enable supervisory control over automated systems. This capability makes them central to manufacturing processes, production lines, and even complex industries like oil and gas, water treatment, food processing, and pharmaceutical manufacturing.

In short, PLCs play an important role by ensuring safety, accuracy, and repeatability—qualities that every industry depends on.

The Role of PLC Programming Services in Process Optimization

While PLC hardware provides the platform, it’s the programming that drives results. Professional PLC programming services deliver the expertise needed for seamless integration into existing systems.

Key Benefits of Expert PLC Programming:

- Reduced downtime through predictive logic and fail-safes.

- Faster cycle times across production lines and machines.

- Quality control improvements by monitoring outputs and alarms.

- Scalability for future growth in industrial settings.

- Significant cost savings through streamlined automated systems.

Well-written PLC programs make it possible to control complex processes while keeping safety and compliance at the forefront. Whether it’s robotics in automotive assembly or batching in chemical plants, programming ensures that operations are smooth and aligned with production goals.

Key Trends in PLC Programming for 2025

Industrial automation is rapidly evolving, and several trends are shaping the future of PLC systems:

- Integration with SCADA, HMI, DCS, and RTUs

The connection between Human-Machine Interface platforms and distributed control systems enables operators to visualize, monitor, and adjust processes in real time. - AI and Predictive Maintenance

By combining data acquisition with AI models, PLCs can detect anomalies and schedule interventions before failures occur. This reduces downtime and strengthens production processes. - Cybersecurity in Industrial Automation

Protecting PLCs and control logic against threats is becoming essential for modern facilities. - IIoT and Cloud Connectivity

Remote monitoring, edge computing, and supervisory control through the cloud allow managers to make informed decisions faster than ever. - Energy Efficiency

Smart programming reduces waste, optimizes energy usage, and contributes to sustainability efforts across industrial settings.

How to Choose the Right PLC Programming Service Provider

When selecting a service provider, businesses should consider more than just cost. Look for:

- Certified engineers with expertise in brands such as Rockwell, Siemens, Schneider, and ABB.

- Proven track record of seamless integration with existing systems.

- Knowledge of communication protocols and modern control logic.

- Experience across various industries like oil and gas, water treatment, automotive, and food manufacturing.

- Understanding of compliance standards (UL, IEC, NFPA).

A qualified provider ensures PLC programs are written for reliability, efficiency, and long-term adaptability, ultimately delivering overall efficiency and reliability.

Case Examples of Process Optimization with PLCs

- Water Treatment Plant: By upgrading PLC systems and adding optimized Ladder Logic, the facility reduced downtime and enhanced safety, delivering significant cost savings.

- Automotive Assembly Line: A new Human-Machine Interface combined with reprogrammed PLCs ensured precise control and quality control while accelerating throughput.

- Pharmaceutical Manufacturing: Enhanced control logic allowed for tighter regulation of complex processes, maintaining compliance while lowering waste.

These real-world examples demonstrate how professional programming creates measurable improvements in industrial processes.

Future of Industrial Process Optimization with PLCs

The future is moving toward digital twins, where simulated models of production processes help refine PLC programs before deployment. Combined with automated systems, supervisory control, and real-time data acquisition, businesses gain unmatched visibility.

Ladder Logic and other programming methods will continue to evolve, while communication protocols ensure smooth data exchange. Factories will depend on PLC systems to deliver both precise control and adaptability.

By 2025 and beyond, businesses using advanced PLC programming will not just meet standards—they will set them, gaining a true competitive edge.

Conclusion

PLC programming services are essential for modern industries looking to thrive in 2025. From production lines to complex processes, PLCs ensure safety, reliability, and measurable improvements in performance.

With the right partner, companies benefit from seamless integration, significant cost savings, and the ability to make informed decisions backed by real-time data. Whether in manufacturing processes, energy, or industrial settings, PLCs remain the backbone of automation.

For businesses seeking to optimize operations, Unicore Automation provides the expertise, innovation, and dedication to help industries move confidently into the future.